The maintenance of dry-type transformers is an importan […]

The maintenance of dry-type transformers is an important operation step of dry-type transformers, and it is also necessary to operate dry-type transformers in daily production and life. Generally speaking, dry-type transformer repair is a must-do for transformer manufacturers every day. So what are the maintenance standards for common dry-type transformers?

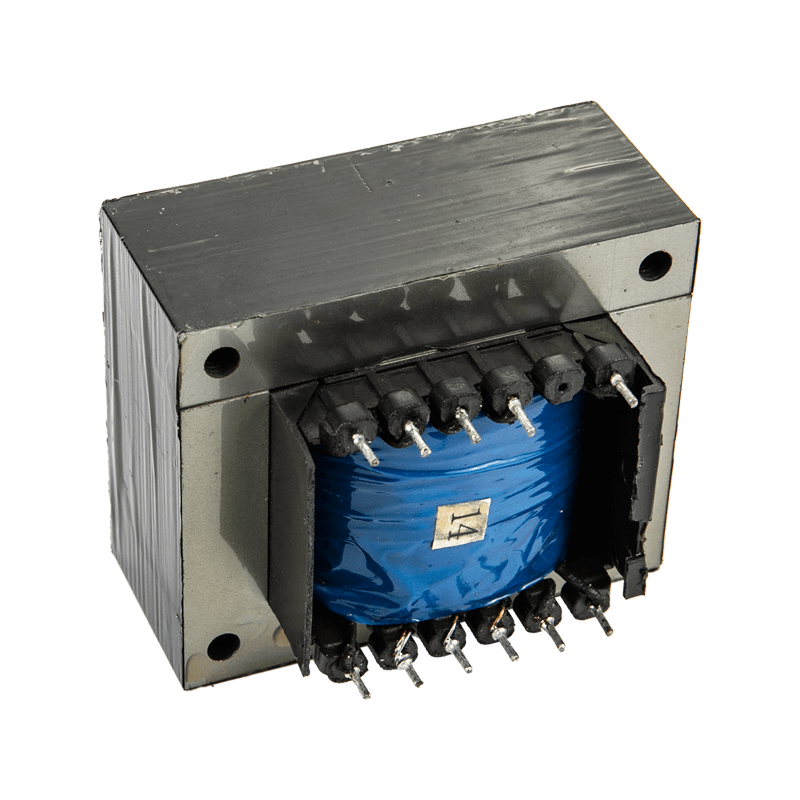

Dry-type transformer

One. Common maintenance standards for dry-type transformers:

1. Run dry-type transformer maintenance once a year, on-site; maintenance is divided into two types

2. The electrical inspection workshop zd is responsible for the maintenance and overhaul of dry-type transformers, and the maintenance is the responsibility of the equipment management department.

3. For dry-type transformer maintenance cycle, items and requirements, please refer to "Railway Power Management Rules". Safety measures must comply with the provisions of the "Railway Electric Power Safety Work Regulations" to ensure the safety of people and equipment.

4. The maintenance of dry-type transformers shall be carried out pre-repair investigation, during-repair inspection, and post-repair inspection and storage. Understand the operating status of dry-type transformers, grasp the existing defects, and determine maintenance items. Through the inspection during the repair, timely discover and correct the problems existing in the repair. After the repair and acceptance, the technical person in charge organizes the repair and inspection personnel and the person in charge of the equipment to participate, and make a record of the acceptance. Run dry-type transformer

After the overhaul, a power transmission inspection should be carried out, and the work can be ended when everything is normal.

5. The maintenance of dry-type transformers should be recorded. Pre-repair survey, overhaul records, and inspection records should be compiled into the dry-type transformer technical files. And to achieve registered maintenance, for reference.

Two, daily use prevention

1. In addition to overvoltage and overload, what is different from oil changes is the fear of moisture.

2. If your transformer has been operating normally, it will not be damp, and the maintenance period can be extended appropriately.

3. How long does it usually take for an overhaul? It depends on the operating conditions and operating environment you are asking about. Generally it is 3 to 5 years. Fortunately, it will be shut down for 3 years, and check whether the various parts of the transformer are loose? Is it contaminated? Is the thermometer normal? Whether the fan can start normally and so on.

4. If the operation is very normal, you can properly clean up some dust after stopping. For other repairs, the transformer manufacturer does not want you to be too active. It can be put into operation.

5. If there are abnormal conditions, such as increased noise, dampness, and pollution. Frequently overloaded, the voltage fluctuates high and low. When the temperature indicator is not normal, stop checking the cause as soon as possible and perform necessary inspections.

Zhejiang Dechuang Transformer Manufacturing Co., Ltd.