The body needs maintenance, the skin needs maintenance, […]

The body needs maintenance, the skin needs maintenance, the car needs maintenance, and the same low-power transformers also need maintenance during use.

1. Prevent over-temperature: The temperature change should be monitored when the low-power transformer is running. Then if the transformer coil wire is A-class insulation, its insulator is mainly paper and cotton yarn, so the temperature has a great influence on the insulation and service life. For every 8 °C increase in temperature, the insulation life will be reduced by about 50%. If the temperature rises to 105°C, the service life is 7 years. If the temperature rises to 120°C, the service life is only two years; the transformer operates at normal temperature (90°C), and the service life is about 20 years. Therefore, when the transformer is running, it is necessary to maintain good ventilation and cooling. If necessary, forced ventilation can be adopted to achieve the purpose of reducing the temperature rise of the transformer.

2. Prevent electric shock: In daily life, the power supply of power transformers is generally obtained through overhead lines, but overhead lines are prone to lightning strikes, so that the transformer will be burned due to breakdown of insulation.

3. Ensure the quality of insulating oil: In the production of low-power transformers, transformers will use insulating oil for storage. In the storage, transportation or operation and maintenance of transformer insulating oil, if the oil quality is poor or there are too many impurities and moisture, the insulating strength will be reduced. When the dielectric strength is reduced to a certain value, the transformer will short-circuit and cause sparks, arcs or dangerous temperatures. Therefore, the transformer should be regularly tested for oil quality during operation, and the unqualified oil should be replaced in time. Favorite the security engineer site.

4. Ensure that the wires are in good contact: the internal joints of the coil are in poor contact, the connection points between the coils, the contacts leading to the high and low-voltage side bushings, and the fulcrums on the tap changer are in poor contact, which will cause local overheating, damage insulation, and short circuit. or open circuit. The high temperature arc generated at this time will decompose the insulating oil, generate a large amount of gas, and increase the pressure in the transformer. When the pressure exceeds the protection setting of the gas circuit breaker without tripping, an explosion will occur.

5. Prevent inadvertent damage to insulation during maintenance: When the transformer is overhauling the hanging core, pay attention to protecting the coil or insulating sleeve. If any scratches are found, it should be dealt with in time.

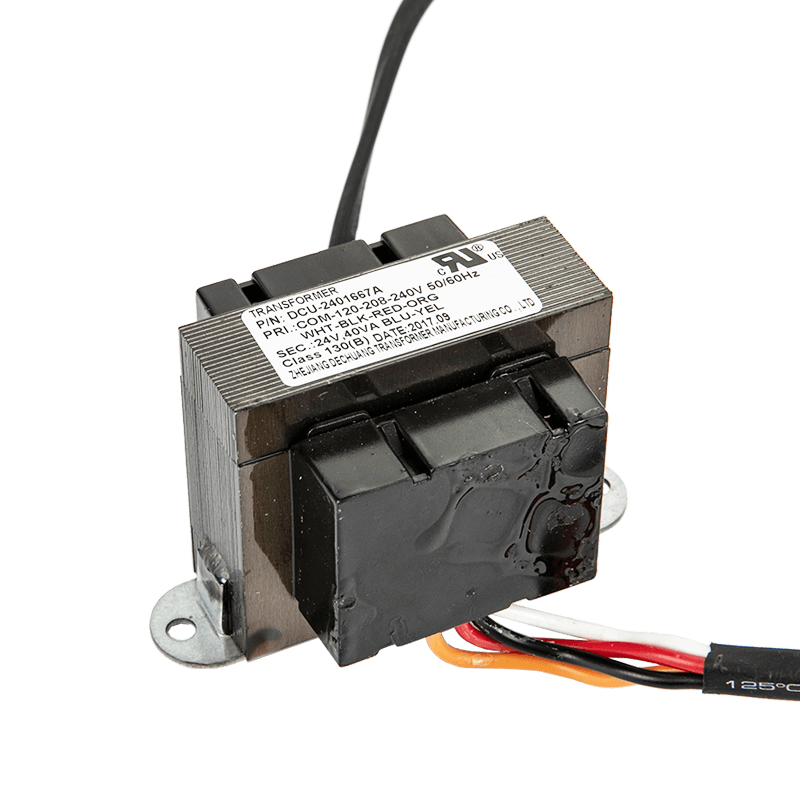

Zhejiang Dechuang Transformer Manufacturing Co., Ltd.