Although toroidal transformers and O-type transformers […]

Although toroidal transformers and O-type transformers are similar in appearance, they are not exactly the same. Many people think of toroidal transformers as O-type transformers, and so do those who are unfamiliar with transformers. From the appearance alone, they are all round, and there is a round hole in the middle. It is easy to mistakenly think that "ring type" is "O type", but if you look closely, there is actually a difference. What is the difference between O-type transformers?

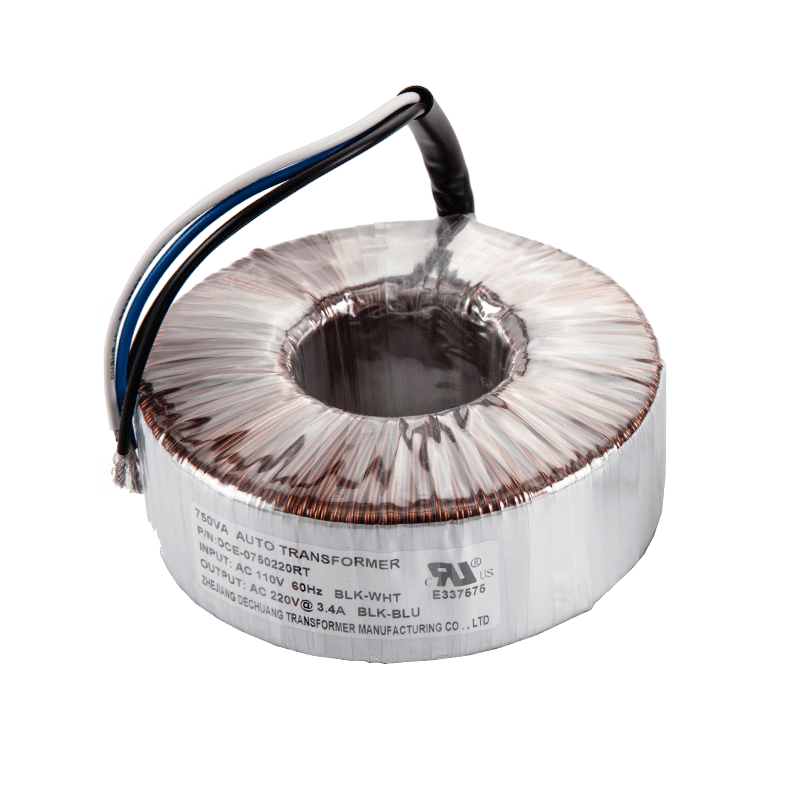

The same between toroidal transformers and O-type transformers is that the cores are round, but from the cross-section of the core, the core interface of the toroidal transformer is square, while the core interface of the O-type transformer is circular.

In addition, the toroidal transformer adopts high-quality cold-rolled silicon steel sheet (generally less than 0.35mm in thickness) and seamless rolling, which makes its core performance better than traditional laminated core. Moreover, the O-type transformer adopts a laminated core structure, which can effectively reduce the eddy current and also reduce the temperature rise of the transformer, because the eddy current is actually another form of energy loss, which is similar to the square transformer.

The toroidal transformer is highly efficient because its core has no air gap, the stacking factor and electrical efficiency are high, and the no-load current is only 10% of that of the laminated transformer. Its windings are evenly wound around the toroidal core, resulting in low magnetic leakage and electromagnetic radiation, and can be used in highly sensitive electronic devices, low-level amplifiers and medical equipment.

Zhejiang Dechuang Transformer Manufacturing Co., Ltd.