In our life, many toroidal transformers are used. Howev […]

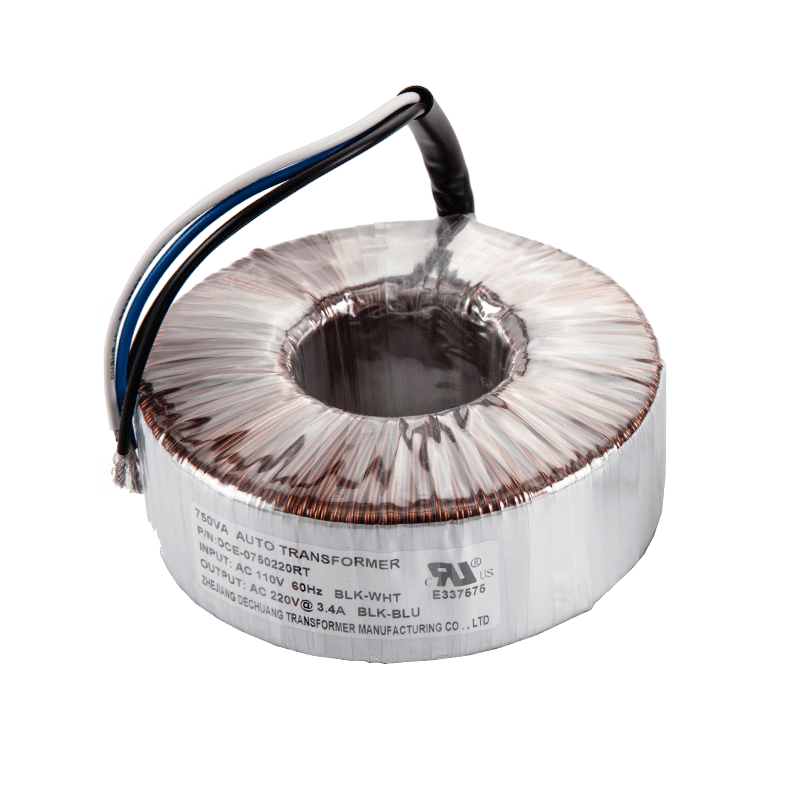

In our life, many toroidal transformers are used. However, the winding method and precautions of toroidal transformer windings may not be clear to most netizens. Here we explain the specific operation methods and precautions for you:

1. First wind the primary winding, take the high-quality high-strength enameled wire with a similar diameter to the original wire, and wrap the double wire on the "I"-shaped wire shuttle, and cut it after the number of turns meets the requirements.

2. Adhere the double thread end to the outer circumference of the annular iron core with double-sided tape, so that the thread shuttle can be wound in the inner hole of the annular iron core.

3. After one layer of coil is wound, apply a layer of insulating varnish (conducive to the positioning and insulation of the turns), wrap a layer with cellophane, and then wind the second layer of coil.

4. Connect the heads and tails of the two coils to make them in series, and the other two wire ends are led out by welding with soft leather wires and insulated.

5. After adding a layer of interlayer insulating paper on the primary group, the secondary winding is wound again, and the winding method is similar to that of the primary winding.

6. After the winding coil is wound, the secondary windings can be wound back in turn in accordance with the rule of "first dismantling and then winding, and then dismantling and first winding".

Note: It is not necessary to count the number of turns when winding, but try to wrap the enameled wire as tightly as possible, and wind one turn by turn without crossing each other. After the previously removed enameled wire is wound, the number of winding turns should be similar to the original number of turns or only 1 to 3 turns less.

Zhejiang Dechuang Transformer Manufacturing Co., Ltd.